Description

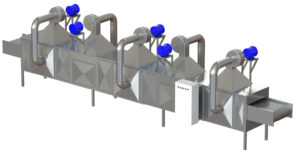

The Chocolate Milling Machine is an advanced industrial solution designed to deliver precise chocolate refining and a smooth, consistent texture for professional chocolate production. Engineered for continuous operation, this machine uses stainless steel ball milling technology combined with accurate thermal control to ensure high-quality results. Its robust food-grade stainless steel construction, energy-efficient Double Jacket tank, and low-noise operation make it ideal for modern chocolate factories seeking reliability, hygiene, and production flexibility.

Specifications

| Model | BCM200 | BCM500 | BCM1000 |

| Machine Dimensions LxWxH (Mm) | 650∅x1100 mm | 1000∅x1300 mm | 1100∅x1850 mm |

| Production Capacity (Kg/Hr) | 250 | 500 | 1000 |

| Power Supply | 3PH-6Kw-50~60Hz | 3PH-14Kw-50~60Hz | 3PH-18Kw-50~60Hz |

Chocolate Milling Machines Overview

Chocolate Milling Machines are essential industrial solutions designed to achieve fine chocolate refining and a smooth, homogeneous texture required for premium chocolate production. These machines are widely used in professional chocolate factories and confectionery production lines where consistency, quality, and thermal stability are critical.

The Chocolate Milling Machine operates using high-quality stainless steel balls that ensure efficient grinding and uniform particle size reduction. This refining process improves chocolate mouthfeel, enhances flavor release, and produces a stable final product suitable for molding, coating, and enrobing applications.

Built for continuous industrial operation, Chocolate Milling Machines combine robust mechanical design with advanced temperature management systems, making them a reliable choice for manufacturers seeking long-term performance and production flexibility.

Chocolate Milling Machine Technology and Performance

Chocolate Milling Machines rely on a proven ball milling system that delivers precise refining control. Stainless steel balls rotate inside the milling chamber, breaking down cocoa solids and other ingredients into extremely fine particles. This process ensures smooth chocolate texture and consistent viscosity throughout the batch.

A complete thermal control system is integrated into the machine to maintain optimal processing temperatures. Proper temperature control is essential in chocolate production, as it prevents overheating, protects cocoa butter structure, and maintains stable flow characteristics. This results in high-quality chocolate suitable for downstream processes such as molding, coating, and wrapping.

The machine’s intelligent design allows for stable performance during extended production cycles, reducing downtime and increasing overall efficiency for industrial chocolate manufacturers.

Production Capacity and Operational Flexibility

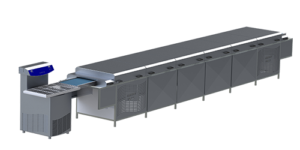

Chocolate Milling Machines are available in multiple production capacities to meet the diverse needs of chocolate factories. Whether used in small-scale specialty production or large industrial operations, the machine can be configured to match specific output requirements.

This flexibility allows manufacturers to scale production without changing equipment, making Chocolate Milling Machines a cost-effective investment. The machine integrates seamlessly into complete chocolate production lines alongside other equipment such as chocolate coating machines, enrobing lines, and molding systems.

You can explore compatible equipment on our chocolate machines page to design a fully optimized chocolate processing line: Al Barary Machines

Double Jacket Tank and Thermal Efficiency

One of the key advantages of Chocolate Milling Machines is the integrated Double Jacket tank. This design feature improves heat retention and ensures efficient temperature distribution throughout the chocolate mass. The double jacket system reduces energy consumption while maintaining stable working conditions during refining.

Efficient thermal management is critical for preserving chocolate quality and ensuring consistent results. The Double Jacket tank supports smooth operation, minimizes temperature fluctuations, and enhances overall production reliability.

Noise Reduction and Operator Comfort

Industrial environments demand machines that are not only efficient but also safe and comfortable to operate. Chocolate Milling Machines are equipped with a soundproofing system that significantly reduces noise levels during operation. This feature improves working conditions, enhances operator comfort, and contributes to a safer production environment.

Reduced noise levels are especially important in continuous production facilities where machines operate for extended periods.

Construction, Hygiene, and Food Safety

Chocolate Milling Machines are manufactured entirely from food-grade stainless steel, ensuring full compliance with international food safety standards. Stainless steel offers excellent corrosion resistance, durability, and ease of cleaning, making it the preferred material for food-processing equipment.

Smooth internal surfaces prevent chocolate residue buildup and simplify cleaning procedures, reducing maintenance time and supporting hygienic production practices. You can learn more about the benefits of stainless steel in food processing from this external resource:

Applications of Chocolate Milling Machines

Chocolate Milling Machines are widely used in:

-

Industrial chocolate factories

-

Confectionery production lines

-

Chocolate refining and processing facilities

-

Premium and specialty chocolate manufacturing

They are suitable for producing refined chocolate bases used in bars, coatings, fillings, and enrobed products.

Why Choose Chocolate Milling Machines from Al Barary Industrial

Chocolate Milling Machines manufactured by Al Barary Industrial are designed to meet the highest standards of performance, hygiene, and durability. With extensive experience in industrial chocolate machinery, Al Barary Industrial delivers solutions that support efficient production, consistent quality, and long-term reliability.

By choosing Al Barary Industrial, manufacturers benefit from professional engineering, robust machine design, and equipment tailored to the demands of modern chocolate production.

admin –

The Chocolate Milling Machine exceeded our expectations. Its stainless steel balls and double jacket tank provide smooth and consistent chocolate refining. The thermal control system keeps the chocolate at the perfect temperature, and the operation is very quiet. Ideal for high-volume industrial production. Highly recommended for chocolate factories seeking efficiency and quality.