Description

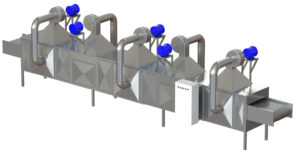

Chocolate Enrober Line systems are essential equipment in modern chocolate factories, designed to coat a wide range of products with compound chocolate or cocoa butter in a smooth, uniform layer. These systems ensure consistent coating quality while maintaining high hygiene standards and efficient production flow.

At Albarary Industries, we design and manufacture industrial Chocolate Enrober Line solutions in Sharjah, UAE, supplying reliable chocolate processing equipment to manufacturers across the Middle East. Our enrobing systems are engineered for durability, precision, and flexibility to meet diverse production requirements.

Date Seed Grinding Machine Specifications

| Model | BCE40 | BDP60 |

| Machine Dimensions LxWxH (M) | 9x1x2 m | 9×1.2×2 m |

| Production Capacity (Kg/Hr) | depends on the product | depends on the product |

| Power Supply | 3PH-12Kw-50~60Hz | 3PH-50Kw-50~60Hz |

Chocolate Enrober Line Overview

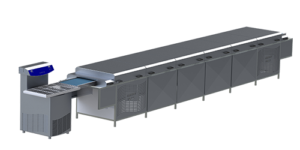

A Chocolate Enrober Line combines an enrobing machine with a cooling tunnel to deliver continuous chocolate coating and controlled cooling. This setup allows manufacturers to coat biscuits, wafers, dates, nuts, bakery products, and confectionery items with consistent thickness and smooth finish.

Compared to manual coating, an automated enrobing system improves productivity, reduces waste, and ensures uniform quality across large production volumes.

What Is a Chocolate Enrober Line

A Chocolate Enrober Line is an integrated chocolate coating system that applies melted chocolate onto products as they pass through a conveyor. After coating, products move through a cooling tunnel where the chocolate sets under controlled temperature conditions.

These systems are widely used in industrial chocolate manufacturing where consistency, hygiene, and production speed are critical.

Importance of Chocolate Enrober Line in Chocolate Production

In commercial chocolate factories, coating quality directly affects product appearance, taste, and shelf life. A chocolate enrobing system helps manufacturers:

-

Achieve uniform chocolate coating

-

Maintain continuous production flow

-

Reduce manual handling and labor costs

-

Improve hygiene and food safety compliance

By using an industrial enrobing system, factories can scale production while maintaining premium product quality.

Key Features of Chocolate Enrober Line

Robust Industrial Structure

The chocolate enrobing system is built with a strong, vibration-free structure designed for continuous industrial operation.

Flexible Cooling Tunnel Lengths

Cooling tunnels are available in different lengths to suit various production capacities and chocolate setting requirements.

Smooth and Consistent Coating

Designed to deliver even chocolate distribution using compound chocolate or cocoa butter.

Easy Operation and Maintenance

User-friendly controls allow operators to adjust coating thickness and conveyor speed with minimal training.

Chocolate Enrober Line Technical Specifications

Available Models: BCE40 & BDP60

-

Machine Dimensions:

-

9 × 1 × 2 m

-

9 × 1.2 × 2 m

-

-

Production Capacity: Depends on product type

-

Power Supply:

-

3PH-12Kw-50~60Hz

-

3PH-50Kw-50~60Hz

-

-

Application: Industrial chocolate coating and enrobing

Custom configurations are available based on factory layout and production requirements.

Applications of Chocolate Enrober Line

Chocolate Enrober Line systems are widely used in:

-

Chocolate factories

-

Date chocolate coating lines

-

Biscuit and wafer production

-

Bakery product coating

-

Nut and confectionery processing

For global chocolate processing guidance, visit the

Food and Agriculture Organization (FAO)

Benefits for Chocolate Factories in the Middle East

Chocolate manufacturers in the UAE and Middle East operate under high temperatures and demanding production schedules. A chocolate enrobing system provides:

-

Stable performance in hot climates

-

Consistent chocolate coating quality

-

Reduced production downtime

-

Improved efficiency and output

These benefits make industrial enrobing lines ideal for regional chocolate producers.

Customization Options

Albarary Industries offers fully customized chocolate enrobing system solutions, including:

-

Cooling tunnel length customization

-

Conveyor width and speed adjustment

-

Chocolate type compatibility

-

Integration with molding, cooling, and packaging systems

Each industrial chocolate coating line is engineered to match your specific production needs.

Hygiene and Food Safety Standards

Our industrial chocolate coating line Line systems are designed to support:

-

HACCP food safety principles

-

ISO hygiene standards

Smooth surfaces and accessible components allow easy cleaning and contamination control. Learn more from the

International Organization for Standardization (ISO)

Integration with Other Chocolate Machinery

Chocolate Enrober Line systems integrate seamlessly with:

-

Chocolate tempering machines

-

Chocolate melting tanks

-

Cooling tunnels

-

Packaging machines

Explore related chocolate equipment on Albarary Machines

Why Choose Albarary Industries

Based in Sharjah, UAE, Albarary Industries is a trusted manufacturer of:

-

Chocolate processing machinery

-

Food production equipment

-

Conveyor and enrobing systems

With regional expertise and a focus on quality, we deliver industrial Chocolate Enrober Line solutions built for Middle East production environments.

Conclusion

A Chocolate Enrober Line from Albarary Industries delivers reliable, hygienic, and high-performance chocolate coating for industrial production lines. With flexible cooling tunnel options, robust construction, and consistent coating results, our systems support efficient chocolate manufacturing across the UAE and Middle East.

admin –

⭐⭐⭐⭐⭐

Reliable and Efficient Chocolate Enrober Line

We installed this Chocolate Enrober Line in our production facility and achieved consistent coating quality with excellent temperature control. The machine is easy to operate, hygienic, and perfectly suited for industrial chocolate production.