Description

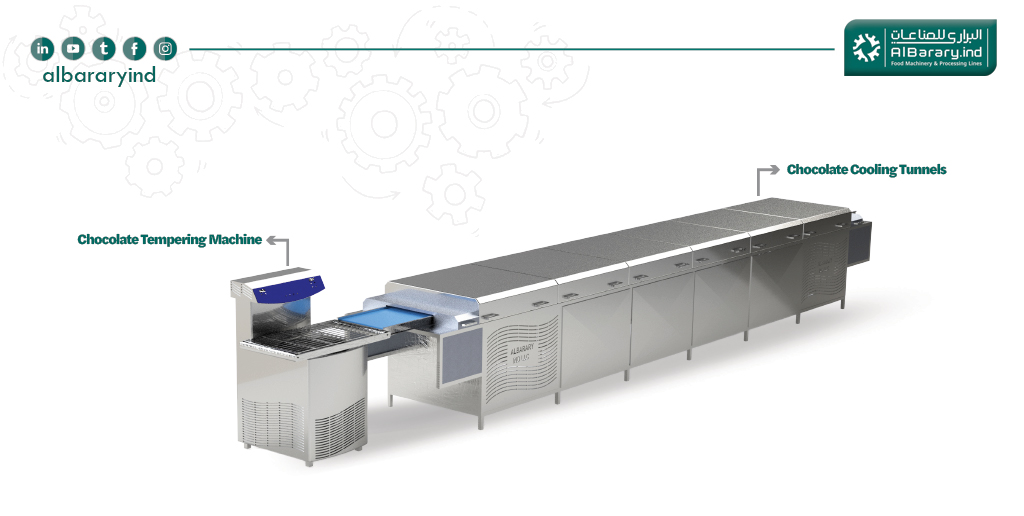

The Enrobing Line for Chocolate is an advanced industrial machine designed to provide smooth, uniform, and high-quality chocolate coating for a wide range of confectionery products. Engineered for continuous production, this machine ensures precise chocolate flow, consistent coating thickness, and reliable performance, making it an ideal solution for professional chocolate factories and high-capacity production lines.

Enrobing Line For Chocolate Specifications

| Model | BCE40 | BDP60 |

| Machine Dimensions LxWxH (M) | 9x1x2 m | 9×1.2×2 m |

| Production Capacity (Kg/Hr) | Depended on the product | Depends on the product |

| Power Supply | 3PH-12Kw-50-60Hz | 3PH-50Kw-50~60Hz |

Enrobing Line For Chocolate – Overview

The Enrobing Line for Chocolate is a high-performance industrial solution designed to provide smooth, uniform, and consistent chocolate coating for a wide range of confectionery and bakery products. This enrobing system is engineered specifically for chocolate made with cocoa butter, as well as compound chocolate, ensuring optimal coating quality, precise temperature control, and efficient continuous production.

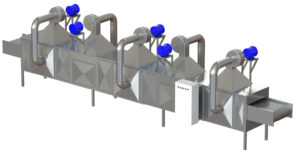

The enrobing line is equipped with cooling tunnels of different lengths, allowing manufacturers to adapt the system to various production capacities and product requirements. This flexibility makes it suitable for both medium-scale and large-scale chocolate factories looking to enhance product quality while maintaining high efficiency.

Enrobing Line For Chocolate – Key Features

The Enrobing Line for Chocolate is designed with advanced technical features that support reliable and hygienic chocolate coating operations:

-

Adjustable cooling tunnels: Available in different lengths to match various production speeds and chocolate crystallization needs.

-

Uniform chocolate coating system: Ensures even coverage on all product surfaces.

-

Compatible with chocolate and compound chocolate: Ideal for cocoa butter-based chocolate applications.

-

Robust industrial structure: Designed for continuous, long-term operation.

-

Easy operation and control: Simplified settings allow operators to manage coating thickness and flow efficiently.

-

Flexible modular design: Can be integrated into existing chocolate production lines.

The machine’s design allows chocolate to circulate smoothly, maintaining optimal viscosity and temperature throughout the enrobing process. This ensures glossy finishes, stable coating layers, and high-quality final products.

Applications of Enrobing Line For Chocolate

The Enrobing Line for Chocolate is suitable for coating a wide variety of products, including:

-

Chocolate bars and centers

-

Biscuits and wafers

-

Cakes and pastries

-

Nuts and confectionery items

-

Filled chocolate products

It is widely used in professional chocolate factories and confectionery manufacturing plants where precision, consistency, and hygiene are critical. The line can be easily combined with other equipment from a complete chocolate production system, such as tempering machines, molding machines, or cooling conveyors.

You can explore compatible equipment for a complete setup on our chocolate machines page: Al Barary Machines

Cooling Tunnel System and Production Efficiency

One of the most important components of the Enrobing Line for Chocolate is its cooling tunnel system. The tunnels are designed to provide controlled cooling conditions that allow chocolate to crystallize properly after coating. Proper cooling ensures:

-

Stable chocolate structure

-

Smooth and glossy surface finish

-

Reduced product defects such as cracking or dull appearance

Different tunnel lengths allow manufacturers to customize cooling time based on chocolate type, product size, and production speed. This flexibility helps factories maintain consistent quality even when producing multiple product types on the same line.

Construction, Hygiene, and Food Safety

The Enrobing Line for Chocolate is manufactured using food-grade stainless steel, ensuring compliance with international food safety and hygiene standards. This construction offers several advantages:

-

Excellent corrosion resistance

-

Easy cleaning and maintenance

-

Long service life in industrial environments

Smooth surfaces and hygienic design prevent chocolate residue buildup and simplify daily cleaning procedures. Learn more about the importance of stainless steel in food processing here:

Advantages of Using an Enrobing Line For Chocolate

Investing in an Enrobing Line for Chocolate provides several production advantages:

-

Consistent and uniform chocolate coating

-

Improved product appearance and quality

-

Higher production efficiency

-

Reduced manual labor

-

Flexible integration with existing production lines

The system’s robust design and reliable performance make it a cost-effective solution for factories aiming to scale production without compromising quality.

Why Choose Al Barary Industrial

The Enrobing Line for Chocolate is manufactured by Al Barary Industrial, a trusted manufacturer of industrial chocolate processing equipment. With extensive experience in food machinery design, Al Barary Industrial delivers solutions that combine durability, hygiene, and high performance.

By choosing Al Barary Industrial, manufacturers benefit from professional engineering, customized production solutions, and reliable after-sales support tailored to modern chocolate production needs.

admin –

“The Enrobing Line for Real Chocolate has transformed our production. The adjustable cooling tunnels and precise coating system ensure every product looks perfect.”